So, what you're saying, it was a positive test?

I wasn't sure I could read your subtle messages so to speak...

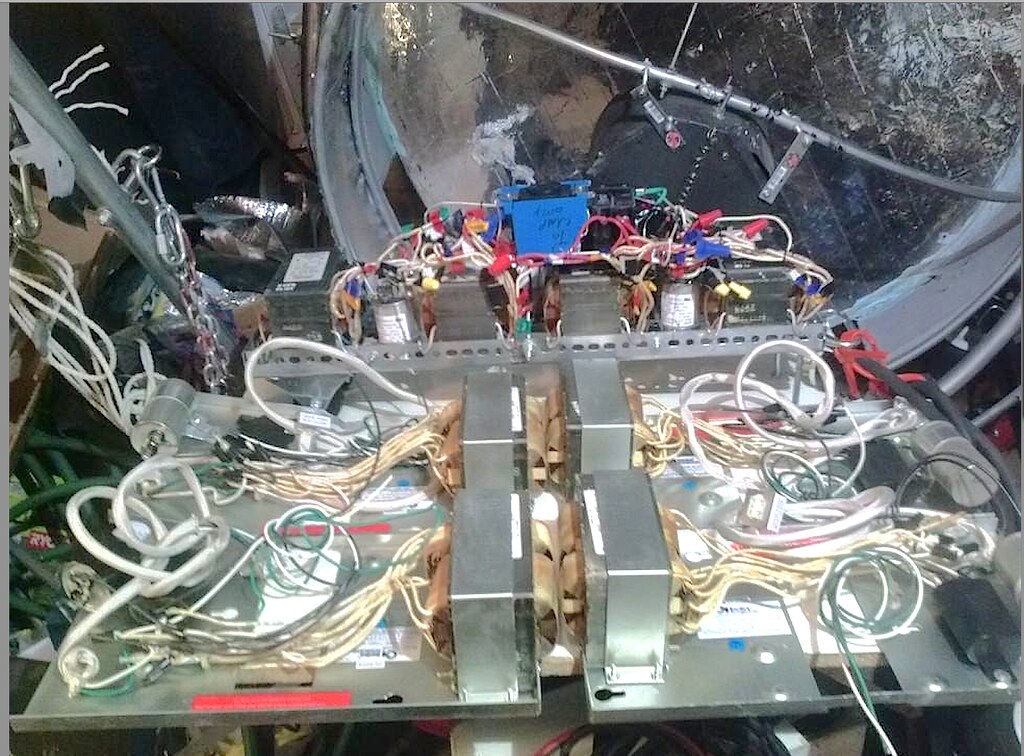

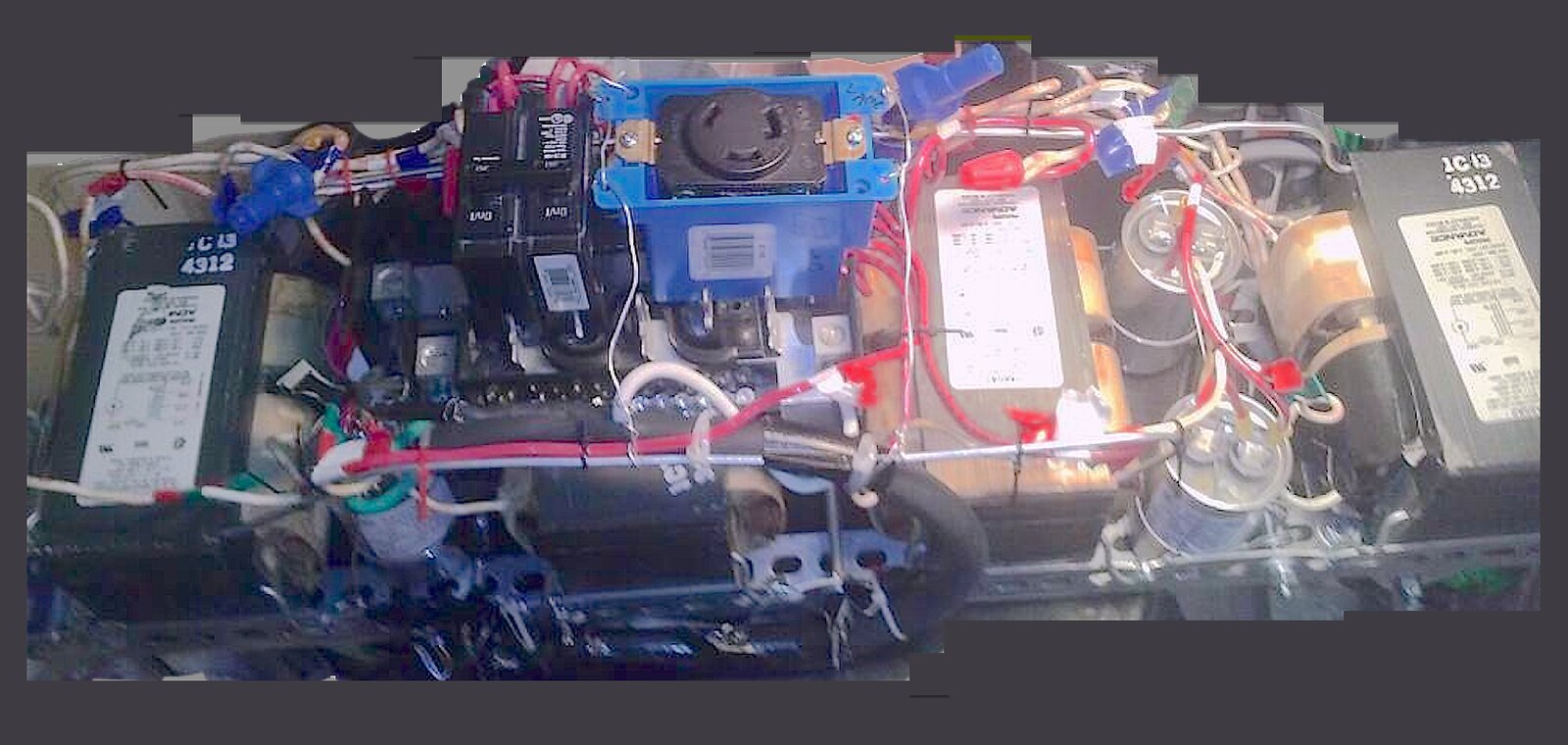

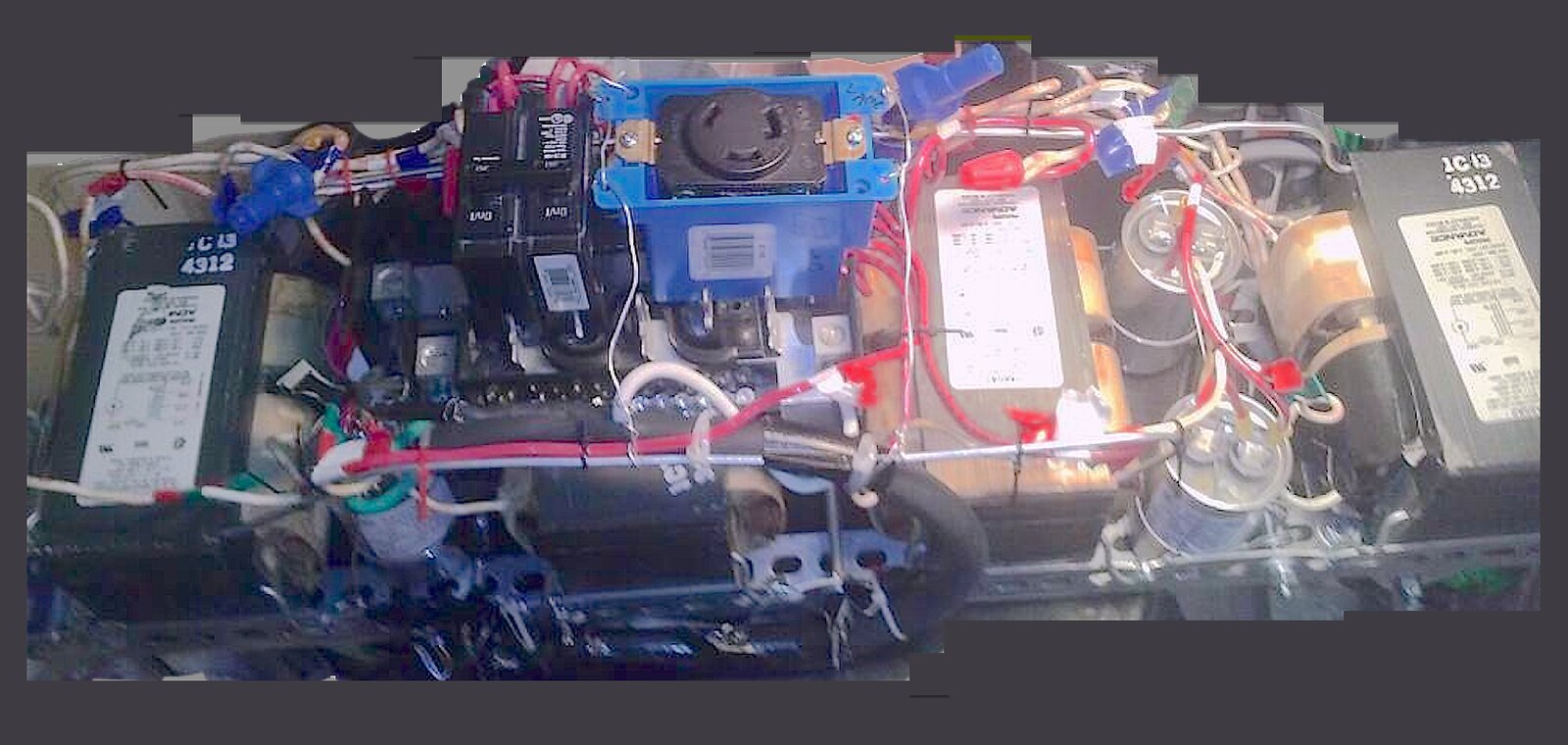

Tried several different wiring configurations when the first test sequence just resulted in a sputtered and blackened bulb. Later realized, while trying several alternate wiring configurations; had by-passed one of the capacitors when removing a jumper cable, wrongly installed earlier on one of the simple capacitor multi-tab terminals, (many possible connections are close together), so I returned the wiring of the ballasts to the configuration as originally designed, and is now working very well. :thumbsup:

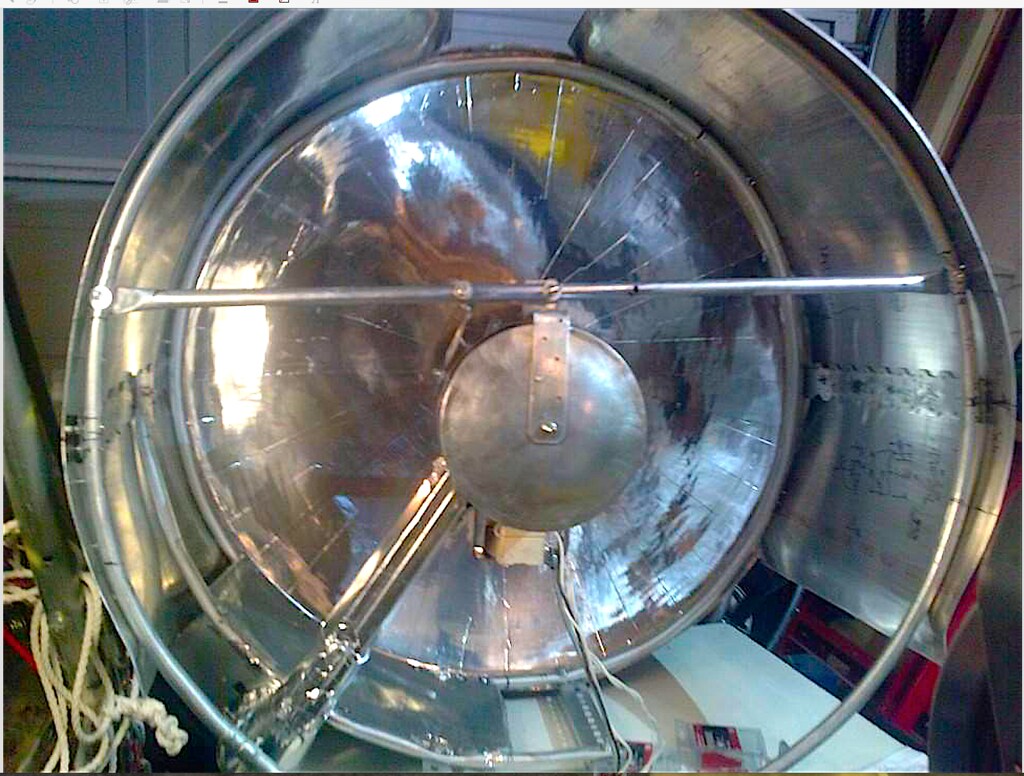

Running the blackened bulb through the "Real Ballast", for sort of a Halide cycle, clearing the bulb in less than fifteen minutes, (whew!),. After wires fixed, the bulb was again fired up on homemade ballast, ready, set, "ignition" went well, but bulb voltages are a little lower than expected, since I'm running 240 into the 277 volt tabs, the lower operating and start-up input voltage of this particular voltage tab of 23% variation, (as my original plan to bring the ballast's normal output voltage down from 265 volts to the 178-237 volt range the bulb is designed to run at, just didn't expect this low of voltage of just under 180 volts, thus the bluer color, (looks the same in sky since the blue color of the air is lit up as normal),., so I will try either the 120 on these this homemade ballast, and/ or just see what happens when I wire up the new expected arrivals with the 240 volt terminals and see if the voltage is about 205-210, which I'd prefer for a "whiter color" and more halide cycling, but if not, the current situation would be adequate. . No problem bringing the voltages up, have to tweak some issues to get input voltages as specified, as this batch of ballasts was very inexpensive because of the commercial voltage ranges ballasts are designed for. Just had to order some inexpensive accessories to remedy the costly low voltage input gauge increases normally associated with standards.

...For my personal searchlights I can use adequate cabling that I wouldn't use in commercial products meant for re-sale.

Am paying a nearly 60% increase in ballast price on the next batch to have more of the common voltages as input tabs, that are more in line with smaller generators commonly found at hardware stores. All the ballasts I work with have 120 volts, but I avoid this like the plague, because the wiring gauge jumps to a dramatically more expensive size that doesn't have to be used with the higher voltages..! The less expensive ballasts use higher voltages more commonly associated with large warehouses, football fields and traffic street lights. My original plan was to use these voltages, but may not be as economical as just purchasing the slightly more expensive ones. However, if I was to make these for the Hollywood set lights that use mostly giant 110 volt cabling, I'd just use the warehouse type ballasts at 120 volts, since these ballasts can handle up to and over 23%, plus or minus, voltage variation. Once electricity is dropped from the transmission and distribution high voltages of the many thousands of volts down to the hundreds of volts, the voltage leaving the transformer drops rapidly with every foot of wire. After several hundred feet, the voltage has dropped substantially, and to lower the costs associated with lighting large areas where voltages would be all over the scale, ballasts with large voltage input ranges were developed, and the fact that these are auto-transformers as well with the power factor capacitor, makes these ideal old school devices..! After having experimented with many different configurations, I'm absolutely amazed at how well these worked, even with all my wiring variations and capacitor changes and placement experiments...Laugh:welcome:

Great learning experience. Now I can make some inexpensive ballasts for the "Big Bright Beasts".

Fingers crossed.:scowl:

Fingers crossed.:scowl:

:thumbsup:

:thumbsup:

HAPPY CAMPER.

HAPPY CAMPER.  I'm ordering more 1,000 watt ballast to make more of these..!:thumbsup:

I'm ordering more 1,000 watt ballast to make more of these..!:thumbsup: ...For my personal searchlights I can use adequate cabling that I wouldn't use in commercial products meant for re-sale.

...For my personal searchlights I can use adequate cabling that I wouldn't use in commercial products meant for re-sale.