I haven't been able to find any pictures of the inside of an A2L head anywhere. So I took the $120-$200 plunge (depending on luck, the supply of used A2Ls on Ebay, when you choose to pick one up, and how good your soldering hand is).

The goal was to replace the secondaries with 3mm 95CRI 2800K warm whites. I considered replacing the main LED, but I didn't have any MCPCBs that would get the emitter at the correct height to be flush with the base of the reflector, which sits on the topmost black plastic ring of the Luxeon. This also seems to be a common problem with modding lights like the U2 Ultra.

My method for softening circa-2000 Surefire glue is to boil a shallow pool of water in in a pot, remove the pot from heat, and drop the head lens-down in the water making sure the level stays below the base. Let it sit there for about a minute before working on it. This helps get both of the threads free.

I opted for a red LED host since the secondary drive current would be lower than that of a white host, and new white LEDs are more efficient than those from 2008. I didn't want them to be blazing bright or overdriven. The downside is that the main beam is driven lighter as well, so it's about ~10 lumens dimmer than the A2L-WH from what I understand. I'm happy with the brightness that resulted. Consider it saved battery life.

It comes apart in 3 sections: lens, driver, and retaining base ring, all unscrewing using that heating method and wrenching with strap wrenches.

With the base ring off, I found a black round aluminum heatsink which is held onto the driver by only the main LED lead wires. Unsoldering them and the sleeve slides up and off. Don't rotate the aluminum heatsink, or you risk breaking solder joints on the main wires.

From there, desolder using a steady hand and patience. Some tips:

- confirm the polarity before setting the height down-- for some reason, I found the original LED anvil polarity was reversed

- solder the leads closer to the inside of the PCB to set the height of the LEDs first, since the outer one is easier to work around

- trim your leads a bit long, then use flush cutters to make them flush after the fact

- have extra 3mm LEDs for when you drop one or more into another dimension

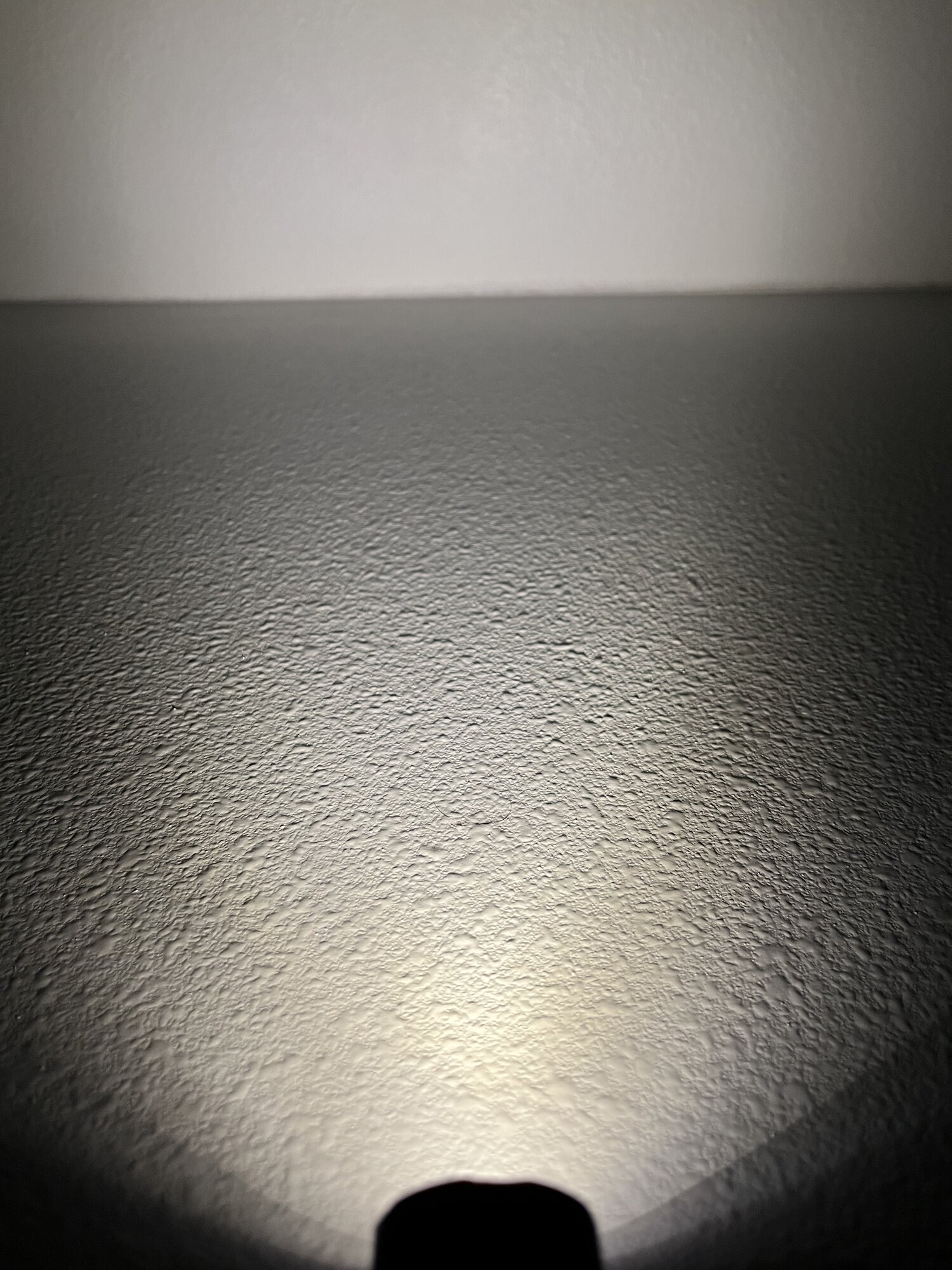

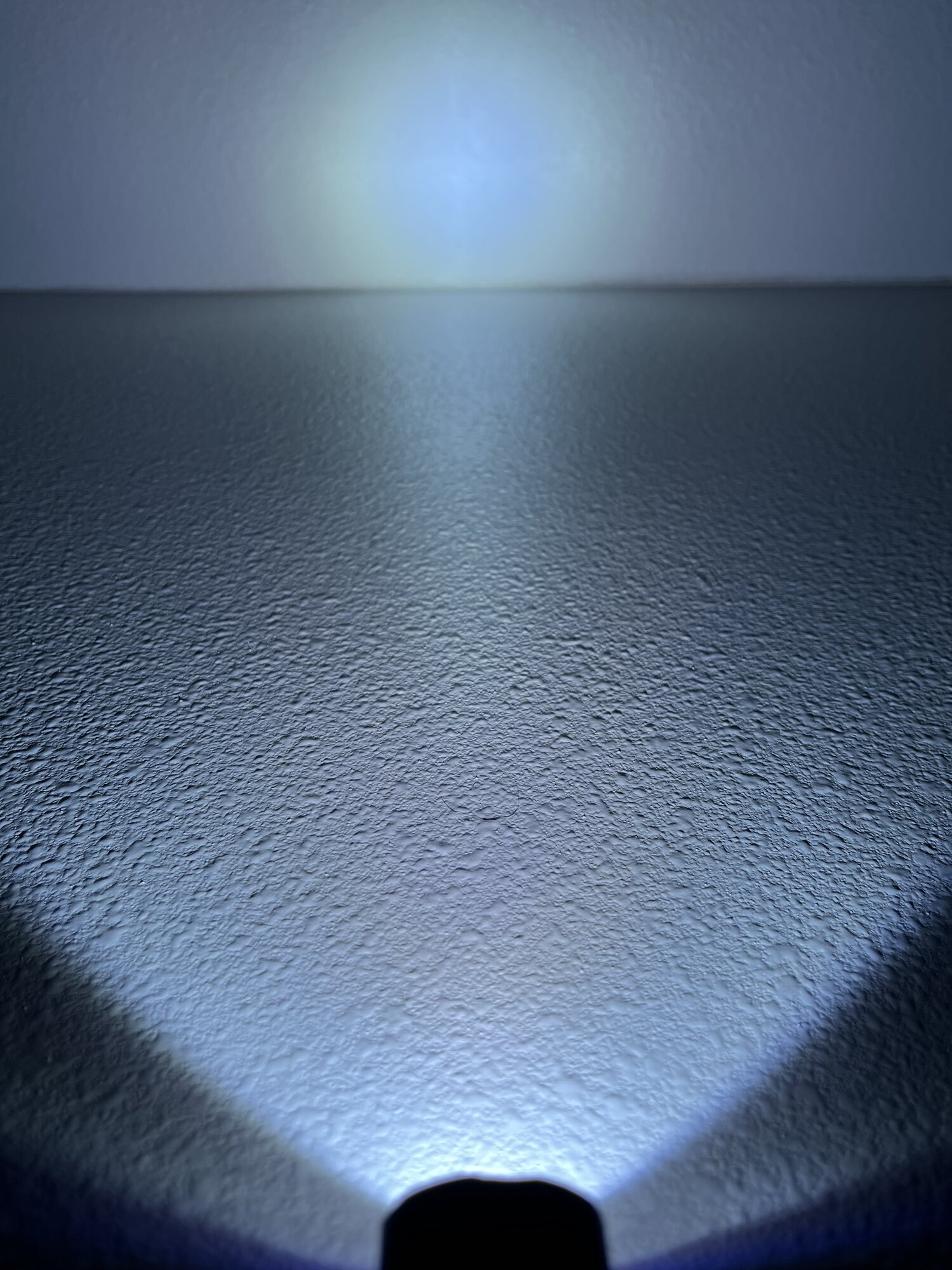

I opted not to sand these like I did the 5mm on my incandescent A2, since the smaller LEDs didn't have as much tint banding. So they have a bit more of a spot shape to them. Results and beamshots:

The goal was to replace the secondaries with 3mm 95CRI 2800K warm whites. I considered replacing the main LED, but I didn't have any MCPCBs that would get the emitter at the correct height to be flush with the base of the reflector, which sits on the topmost black plastic ring of the Luxeon. This also seems to be a common problem with modding lights like the U2 Ultra.

My method for softening circa-2000 Surefire glue is to boil a shallow pool of water in in a pot, remove the pot from heat, and drop the head lens-down in the water making sure the level stays below the base. Let it sit there for about a minute before working on it. This helps get both of the threads free.

I opted for a red LED host since the secondary drive current would be lower than that of a white host, and new white LEDs are more efficient than those from 2008. I didn't want them to be blazing bright or overdriven. The downside is that the main beam is driven lighter as well, so it's about ~10 lumens dimmer than the A2L-WH from what I understand. I'm happy with the brightness that resulted. Consider it saved battery life.

It comes apart in 3 sections: lens, driver, and retaining base ring, all unscrewing using that heating method and wrenching with strap wrenches.

With the base ring off, I found a black round aluminum heatsink which is held onto the driver by only the main LED lead wires. Unsoldering them and the sleeve slides up and off. Don't rotate the aluminum heatsink, or you risk breaking solder joints on the main wires.

From there, desolder using a steady hand and patience. Some tips:

- confirm the polarity before setting the height down-- for some reason, I found the original LED anvil polarity was reversed

- solder the leads closer to the inside of the PCB to set the height of the LEDs first, since the outer one is easier to work around

- trim your leads a bit long, then use flush cutters to make them flush after the fact

- have extra 3mm LEDs for when you drop one or more into another dimension

I opted not to sand these like I did the 5mm on my incandescent A2, since the smaller LEDs didn't have as much tint banding. So they have a bit more of a spot shape to them. Results and beamshots:

Last edited: