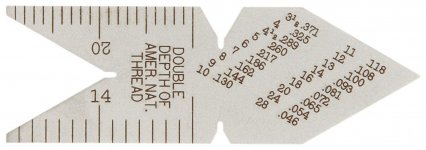

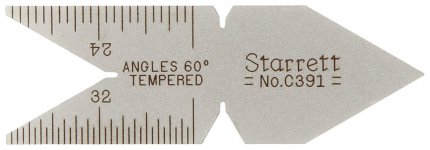

Well this is my first threading operation on my new lathe and I am pleased how it came out.

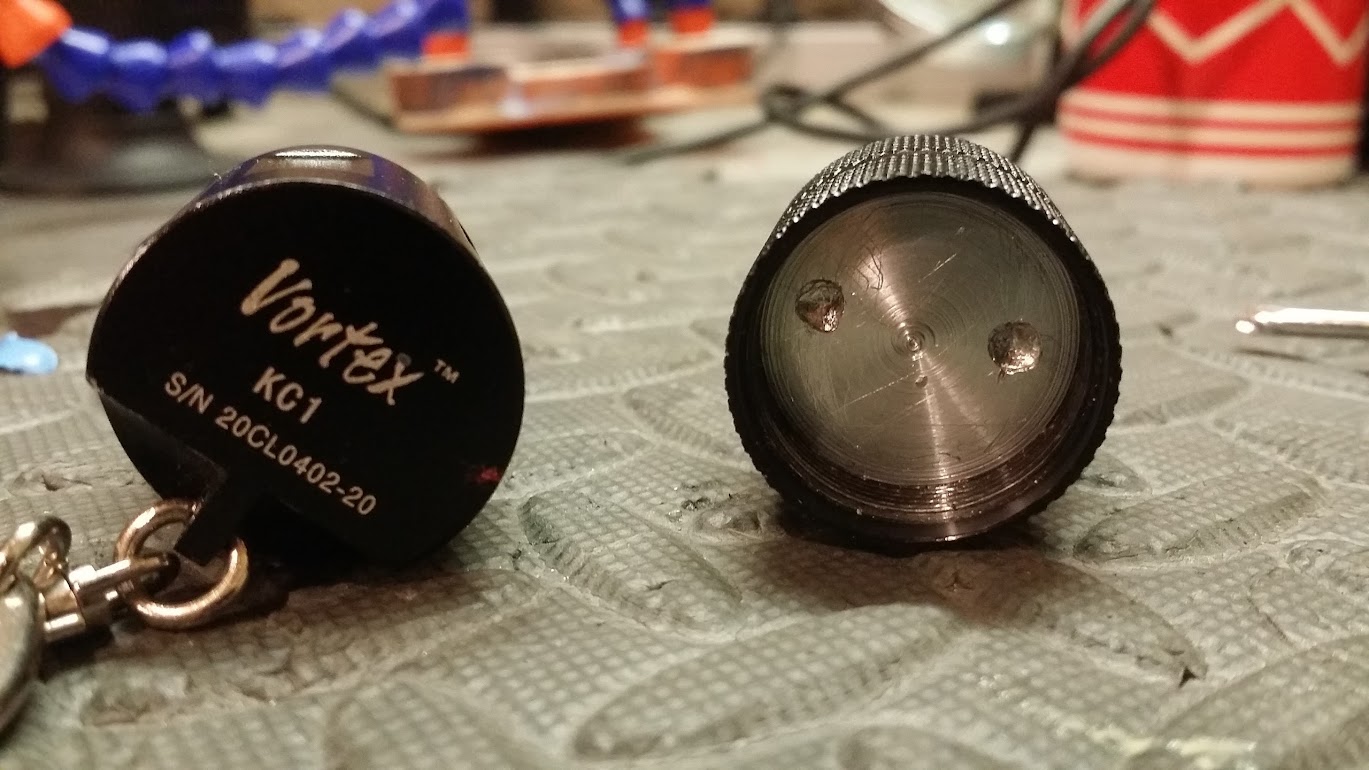

This light will be bored to use 1, 18350 and most likely have a triple of some type installed. I would have made it out of copper but I did not have some with a large enough diameter, and I didn't know how it would turn out so I went with aluminum for my first go. Of course this is still a work in progress but I was excited that I made this work.

The orignial Vortex light was a horrible design but once I am finished this will be a nice light. Here's some photos for you guys.

This light will be bored to use 1, 18350 and most likely have a triple of some type installed. I would have made it out of copper but I did not have some with a large enough diameter, and I didn't know how it would turn out so I went with aluminum for my first go. Of course this is still a work in progress but I was excited that I made this work.

The orignial Vortex light was a horrible design but once I am finished this will be a nice light. Here's some photos for you guys.