precisionworks

Flashaholic

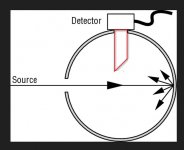

I was able to remove the straight cut tube that points down from the sensor port (painted flat black inside) & replace it with a 45° angle cut tube painted flat white inside. The long point of the 45° cut faces the light port so that any spill will hit the point & be reflected. The opposite side of the tube is in the shadow of the 45° point, so no direct light can strike the inside of the tube. The reason for the flat white is to try to match the reflectance of the Styrofoam interior.

The output of the lights are still in the same order except that the U2 moves above the E1B. I played with the radius squared numbers and settled on 18 as being as close to published figures as possible. 18 = 4.24" radius, or about 8.5" internal sphere diameter. Best scientific guess is that the Styrofoam is not as bright as a commercial sphere, so my 10" is producing results like a commercial 8.5" sphere.

Latest (hopefully last) revision. Here are the readings. First reading is my lumen calculation, followed by factory stated lumens:

Mac's Custom P7 (AW C-cell LiIon) = 782 lumens (about 800 per Mac)

Malkoff M60 with 60Ω Sandwiche Shoppe mod = 15/192 lumens (235 per Malkoff website)

Surefire U2 = 7/114 lumens (2/100 per SF)

Surefire E1B = 11/113 lumens (5/80 per SF)

Novatac 120P = .23/11/99 lumens (.23/10/120 per NovaTac)

Muyshondt Aeon = 10/92 lumens (?/114 per Muyshondt site)

Muyshondt Nautilus = 6/91 lumens (?/107 per Brightguy site)

McGizmo LunaSol 20 = 9/73 lumens (9/78 per Don)

Surefire L4 = 66 lumens (100 per SF)

M60LL in Surefire G2 = 61 lumens (80 per Malkoff site)

Surefire E2L (single stage Cree) = 57 lumens (45 per SF)

McGizmo SunDrop = 46 lumens (40-50 per Don)

Surefire E1L (single stage Cree) = 40 lumens (30 per SF)

Muyshondt CR2 Ion = 3/29 lumens

Surefire KL1 (Luxeon) head = 29 lumens

Gerber Trio (2 AA Lithium) = 22 lumens (24 per Gerber)

The output of the lights are still in the same order except that the U2 moves above the E1B. I played with the radius squared numbers and settled on 18 as being as close to published figures as possible. 18 = 4.24" radius, or about 8.5" internal sphere diameter. Best scientific guess is that the Styrofoam is not as bright as a commercial sphere, so my 10" is producing results like a commercial 8.5" sphere.

Latest (hopefully last) revision. Here are the readings. First reading is my lumen calculation, followed by factory stated lumens:

Mac's Custom P7 (AW C-cell LiIon) = 782 lumens (about 800 per Mac)

Malkoff M60 with 60Ω Sandwiche Shoppe mod = 15/192 lumens (235 per Malkoff website)

Surefire U2 = 7/114 lumens (2/100 per SF)

Surefire E1B = 11/113 lumens (5/80 per SF)

Novatac 120P = .23/11/99 lumens (.23/10/120 per NovaTac)

Muyshondt Aeon = 10/92 lumens (?/114 per Muyshondt site)

Muyshondt Nautilus = 6/91 lumens (?/107 per Brightguy site)

McGizmo LunaSol 20 = 9/73 lumens (9/78 per Don)

Surefire L4 = 66 lumens (100 per SF)

M60LL in Surefire G2 = 61 lumens (80 per Malkoff site)

Surefire E2L (single stage Cree) = 57 lumens (45 per SF)

McGizmo SunDrop = 46 lumens (40-50 per Don)

Surefire E1L (single stage Cree) = 40 lumens (30 per SF)

Muyshondt CR2 Ion = 3/29 lumens

Surefire KL1 (Luxeon) head = 29 lumens

Gerber Trio (2 AA Lithium) = 22 lumens (24 per Gerber)

Last edited: