I've looked into this before, but decided to try to make my own custom tailcap boots. Basically create a mold so I can make custom colors, or glowy boots or whatever I feel like. The end goal would be to make a boot that has my own design, but that would take more time for me to get comfortable with the 3D program Blender.

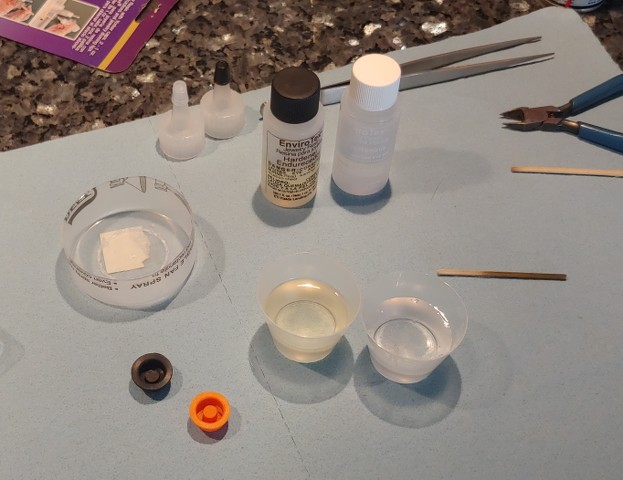

So for my first trials, I'm copying existing 6P style boots, using a 2-part resin to create the mold. Unfortunately, the resin I purchased has something like a 24 hour cure. I did the first half of the mold this morning, and will see how it turned out when I get back in town in a couple days.

Here I'm setting up for the pour

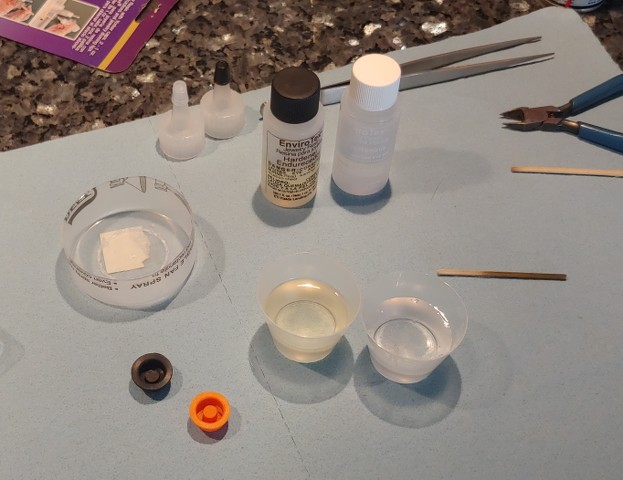

Second image is of the two boots placed where I want them. I've used a bamboo skewer to act as the sprue points. I'll refine the pathways with a dremel tool when its fully cured.

I coated the boots with WD-40 as a release agent, because that's what I had on hand. That's why the exposed part of the boots look wet, that's not epoxy.

_Daniel

So for my first trials, I'm copying existing 6P style boots, using a 2-part resin to create the mold. Unfortunately, the resin I purchased has something like a 24 hour cure. I did the first half of the mold this morning, and will see how it turned out when I get back in town in a couple days.

Here I'm setting up for the pour

Second image is of the two boots placed where I want them. I've used a bamboo skewer to act as the sprue points. I'll refine the pathways with a dremel tool when its fully cured.

I coated the boots with WD-40 as a release agent, because that's what I had on hand. That's why the exposed part of the boots look wet, that's not epoxy.

_Daniel