PhotonFanatic

Flashlight Enthusiast

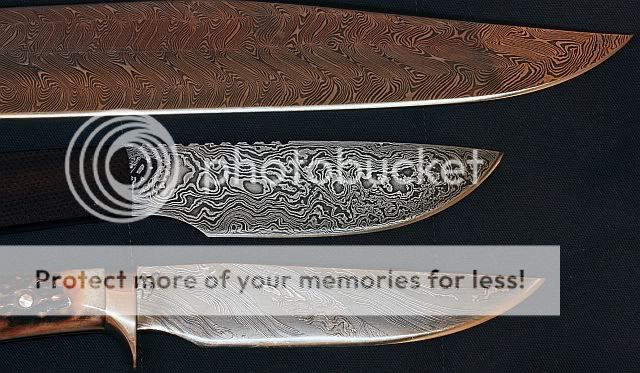

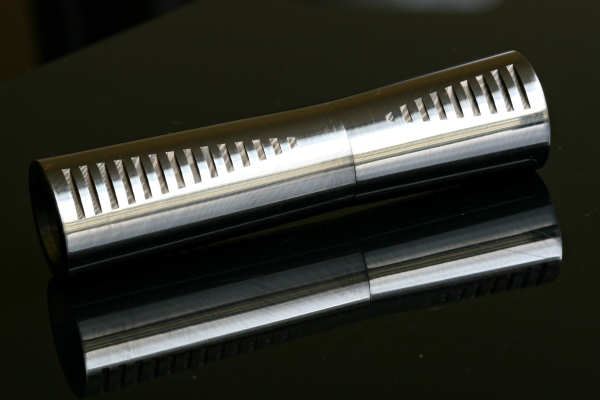

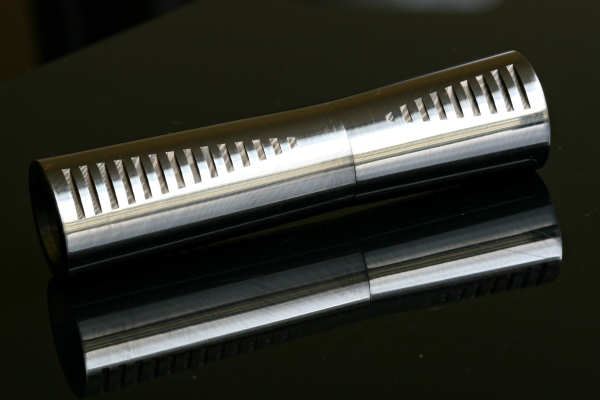

Completed polishing on all nine SS Damascus lights today. Tomorrow the etching of a test piece will take place and then each side of a 20 mm disc will be darkened, but using different techniques. After that is done, I'll decide which technique to use for all the lights.

Of the nine lights that I've built, six of them are now spoken for, and the three remaining lights might make it to a sales thread. I say 'might', only because a few folks can't seem to wait. :devil:

These lights are taken:

The three below are still available:

Of the nine lights that I've built, six of them are now spoken for, and the three remaining lights might make it to a sales thread. I say 'might', only because a few folks can't seem to wait. :devil:

These lights are taken:

The three below are still available: